|

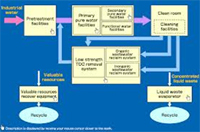

Manufacturing of wafers includes processes like etching, diffusion, photoresist, photomask etc and after each process there is a rinse step. As the microcircuits are as small as 45 to 18 nanometer, rinse water quality has to be Ultrapure Water meeting ASTM D5127-99 standard as minimum. Ultrapure Water System removes ionic impurities upto ppt level and in addition parameters like Boron, Dissolved Oxygen, particles, TOC also should be at very low level.

UPW system includes several process steps to achieve such stringent specifications. The plant equipments are manufactured out of high purity materials like PVDF. |